from august 16, 2021, to august 27, 2021, in order to implement the content of the "action plan for cultivating first-class undergraduate talents of northwestern polytechnical university," deepen the reform of practical teaching and practice the work of educating people in practice,qmes organized a 10-day production internship for 123 undergraduates at the engineering training center on chang'an campus. this practice comprises nine modules covering cold processing, thermal processing, electronic teaching, modern engineering teaching, etc..

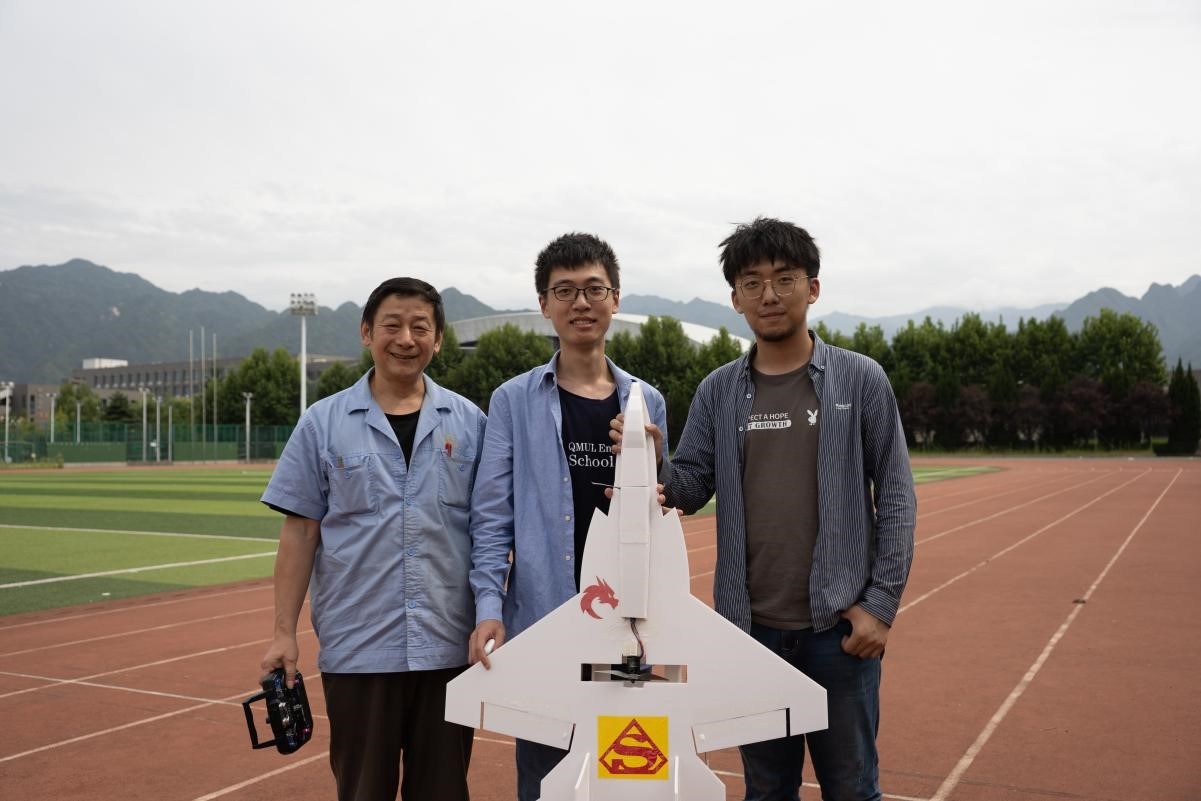

production internship of model aviation innovation design

ten students learned the basics of model aviation, design ideas and concepts, and the basic principles and techniques of using laser cutting machines with the guidance of their teachers. the essential thing in the process is the use of different design software. autocad, the primary tool for designing aviation model structures, is mainly used for two-dimensional drawing. photoshop and coreldraw are practical tools for creating and editing bitmap and vector graphics. eagleworks is used to design the working optical path of laser cutting machines.

electronic teaching & cold processing teaching

the electronics production internship requires students to have some knowledge of circuit boards and programming. the students designed their circuit boards and programmed them so that they could eventually run simple games. in the internship course, teachers explained some drawing knowledge and led the students to create the circuit board on the computer with the corresponding program.

virtual reality simulation technology

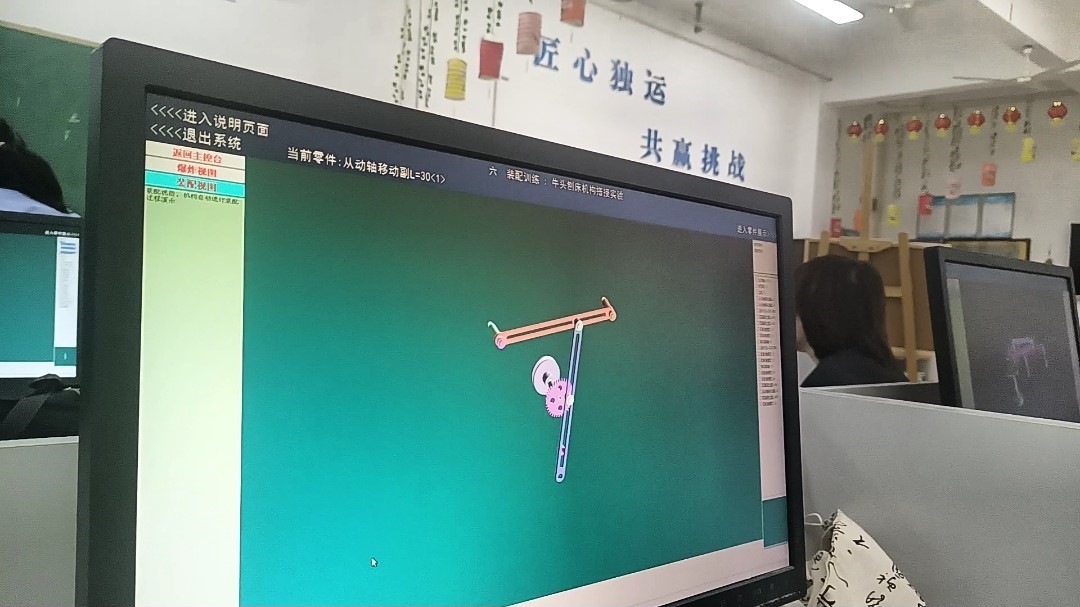

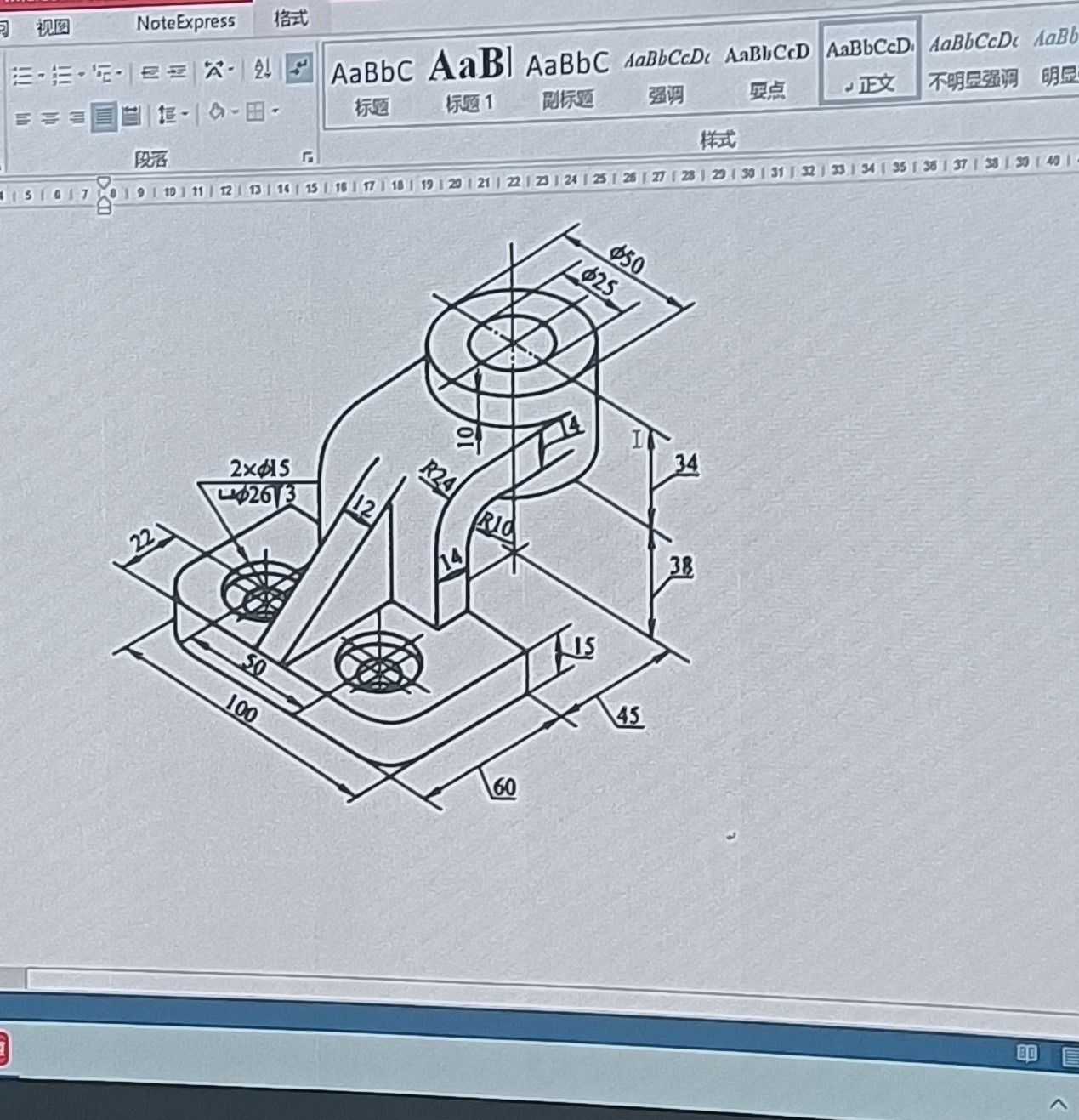

in this vr simulation technology course, students mastered flat mechanism assembly, vr simulation assembly, catia use, 3dsmax use, and ideavr use. during the internship, students started with a group as the base point and worked on the design of live machine assembly, virtual assembly, assembly parts, and assembly animation in turn. in this vr course internship, students learn a lot about assembly-related knowledge and improve machining efficiency by combining the actual mechanical assembly process with modern vr scientific technology through vr as a technological tool.

plane mechanism assembly training record

the physical picture of vr equipment

catia design assignment diagram

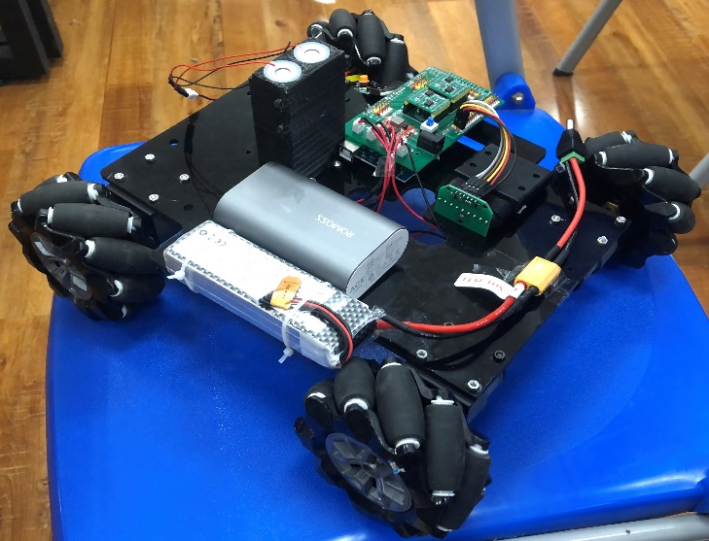

robot design and production

in the robot design and production (wheeled robot direction) production internship, students had learned tiny robots' hardware principles and software programming. they knew the principles of wheeled robots and related operations of relevant machining equipment.

wheeled robots are easy to handle, have plenty of room for adaptation and can be used in conjunction with what they have learned. the students designed a multifunctional robot with the goal of efficient and uniform humidification. with a water tank, humidifier and fan on the base of the robot's cart, it can be applied to indoor disinfection operations during epidemic prevention and control. robots can replace humans in dangerous environments by installing robotic arms to complete functions such as grasping and handling.

intelligent robot system teaching and innovation practice

with the guidance of teachers in the industrial training center, students experienced the whole process from designing drawings, drawing parts, assembling parts, printing parts to physical assembly and then debugging procedures to check the structure, learned relevant knowledge about 3d printing and laser cutting, as well as mastered the use of software such as ug and caxa cad.

basic internship

during the ten-day basic production internship, the teachers guided the students to do the work related to turning, milling, and clamping. they experienced the complete process of making a metal hammer from a rough metal bar. when carrying out turning and milling, the precise scales of each machine, the mathematical formulas requiring careful calculations, and the strictly controlled operating procedures all gave the internship students an experience of the charm of industrial production. while working as millwrights, the students learned to polish rectangular pieces of metal with wire saws and files, which took over a dozen hours. the two steps of turning and milling taught the students to be rigorous, and the pincer work tempered the students' patience. the students were excited beyond words when the thread screwed together with the metal hammerhead and the metal hammer handle. it was the first time that theoretical knowledge was put into practice by actually building an object. it was also a new and exciting experience for the students.

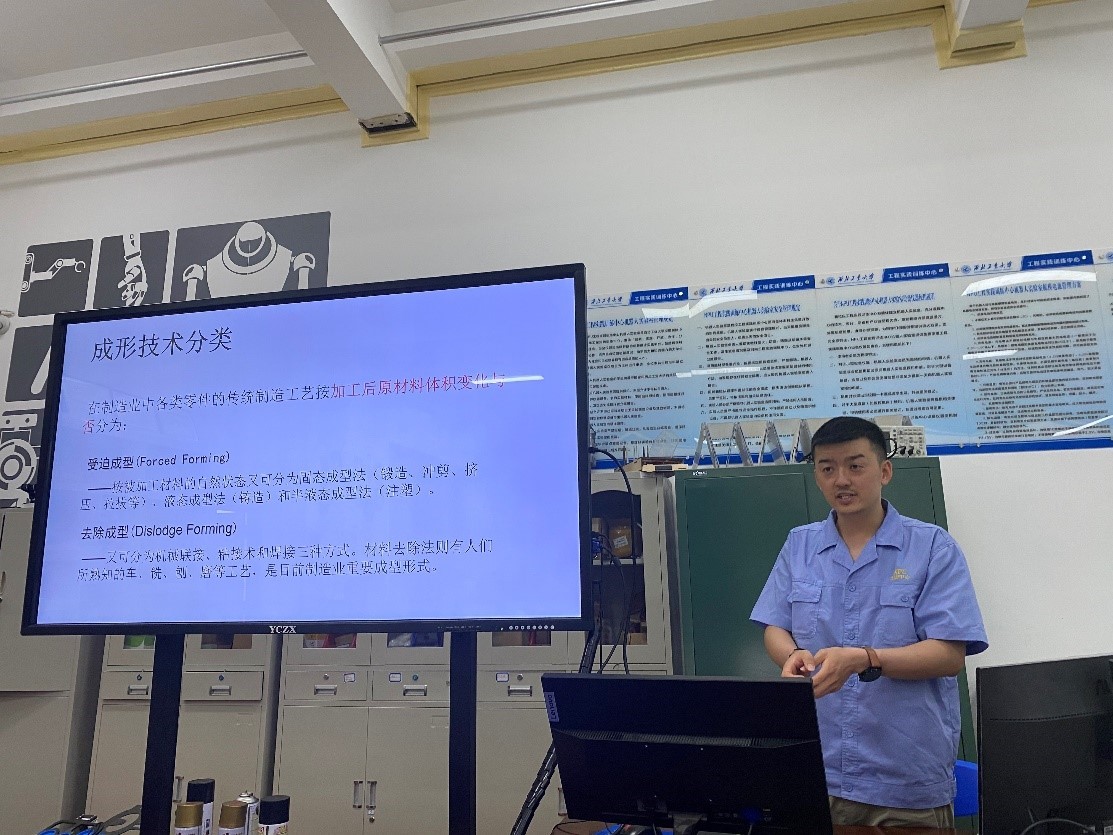

hot working technology

in this hot summer, the epidemic and the heat were tested heavily, yet the students overcame the difficulties and consistently participated in the production internship organized by the college. during the casting internship, the students mainly learned sand casting, which used a specific ratio of clay and other materials mixed with sand to cover the prototype's surface. finally, students made the sandbox mold through the process of grooving and sand filling. in the heat treatment practice, the teacher led the students to experience the process of quenching and tempering different parts from the principle of phase change of metal. the students also tried free forging, die forging, arc welding, shielding gas, and the relatively technically demanding argon arc welding with the guidance of their teachers.

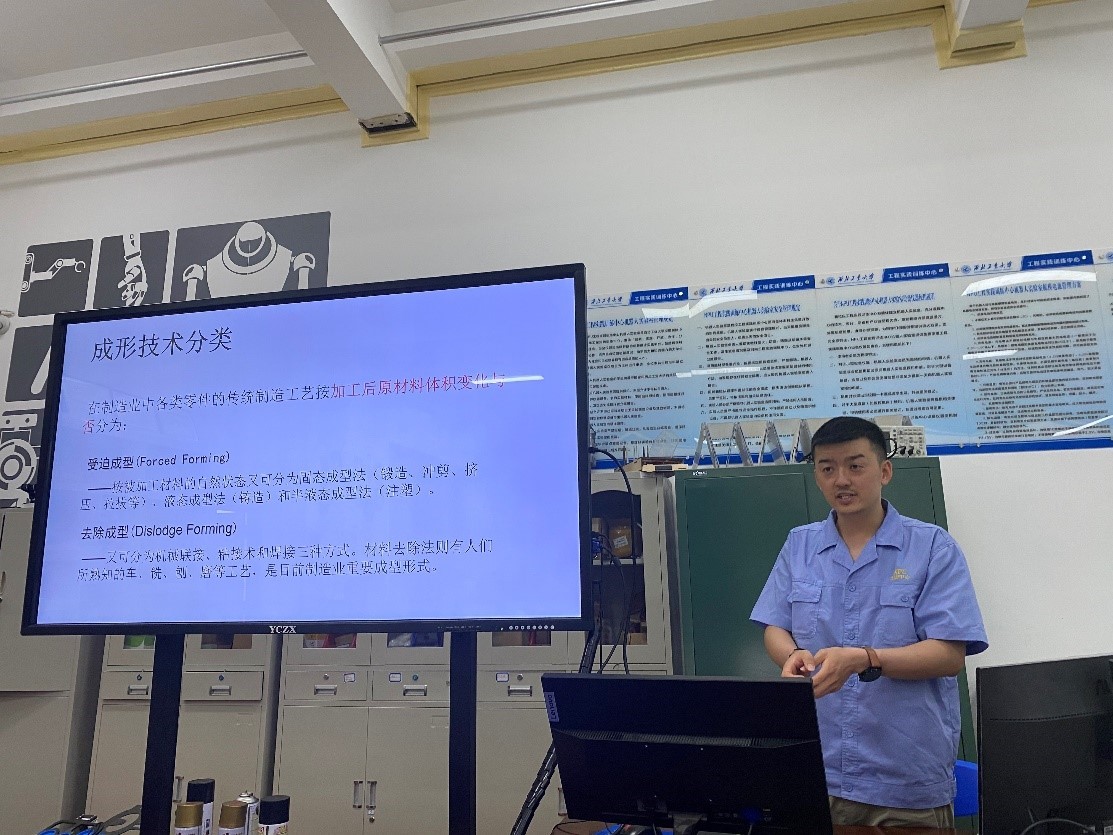

advanced manufacturing technology

during the first two days of the advanced manufacturing technology internship, the teacher explained the programming functions of the software and the instruction codes of the cnc machine, and the students learned how to use ug10.0 software to draw parts and assemble them. with the teacher's guidance, the students learned how to operate the cnc milling machine and cnc lathe, machined the internal bar, connecting rod, and other parts by hand, and learned how to use the 3d printer to make footpads.

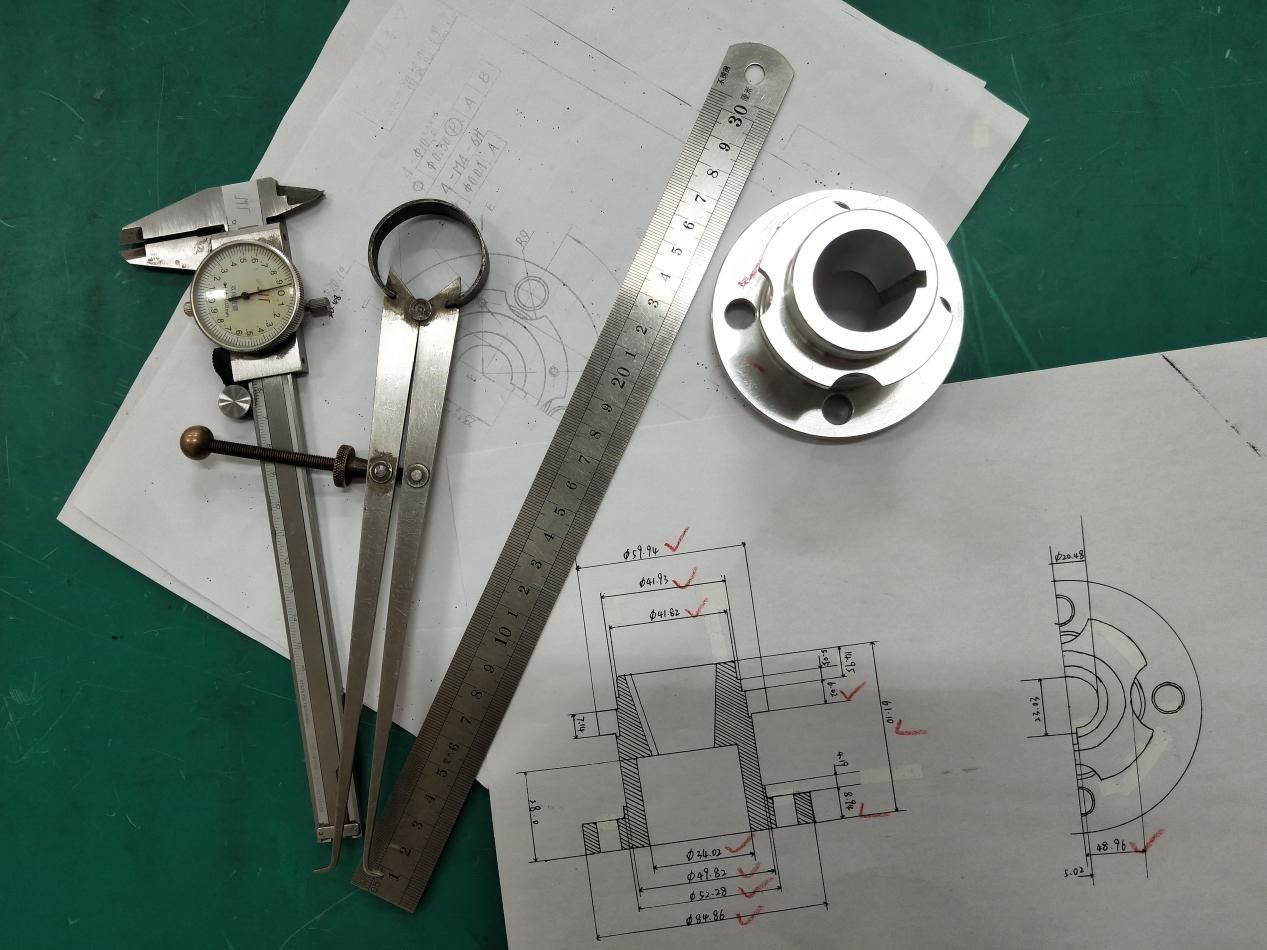

integrated production internship

the students participating in this comprehensive production internship program were divided into five groups to experience the different types of work in turn in the order of turning, milling, clamping, cnc, and inspection processes.

lathe work

turning is a method of machining with a lathe. the teacher introduced the main processing range, model, and lathe usage to the students in detail. with the guidance, the students learned to operate the lathe and independently completed processing a cylindrical plexiglas material to get a gyroscope prototype.

milling work

milling is the method of machining with a milling machine. the teacher showed the students the similarities and differences in the operating principles of milling machines and lathes by analogy to have a clearer understanding of milling machines and lathes. the milling process usually works in conjunction with the wire cutting process. wire cutting is a processing method that uses a moving metal wire as the tool electrode and passes a pulse current between the wire and the workpiece to cut the workpiece using the corrosion effect of the pulse discharge. because of the operating system's robust calculation and path drawing functions, it is possible to quickly and easily machine the outer contours of workpieces and delicate surfaces with greater precision and refinement than with manually operated milling machines. the students also practiced rough machining of cylindrical alloy steel material with the guidance of the instructor.

benchwork,

the students experienced a big difference when they were doing their clamping practice. while other machining processes are done with the help of machine tools, clamping, by contrast, is more of a manual process. the teacher explained that the clampers could do some machining that is not suitable for mechanical methods. it needs benchwork to maintain and repair when machinery is malfunctioning and damaged. benchwork is time-consuming and labor-intensive, but the precision and flexibility are much higher than mechanical equipment. as the saying goes, "slow work makes perfect work."

grinder work

students who have experienced milling are no strangers to grinders. the most significant difference between a grinder and a milling machine is that the cutting tool is a grinding wheel instead of a milling cutter. in this project, the students performed further finishing on the milled rough workpiece.

numerical control and inspection process

a cnc machine tool is an automated machine tool equipped with a program control system. the control system can logically process programs with control codes or other specified symbolic instructions, decoding them and representing them in codified numbers fed into the cnc through an information carrier. inspection and process design is a systematic and scientific arrangement for the design of the processing process before the start of the process, and a check on the quality of the product after the process is completed. this is an essential process to ensure the viability and safety of the product.

the significance of this production internship is to implement the principle of linking theory to practice. students are directly involved in the production process in the capacity of actual workers. they went from the classroom to the workshop. they saw how the professional technicians skillfully applied the theoretical knowledge of the profession to the essential operation, and also learned the actual production technology knowledge as well as the management knowledge and mastered the production skills. in the future, the school will take moral education as fundamental, taking the maximum advantages of the school in international talent training and practical education functions, focusing on the improvement of students' innovation ability, and helping cultivate high-quality international innovative talents.

text by 2018 undergraduate students of qmes

photo by 2018 undergraduate students of qmes

edited by sijia wu

review by xiaoli fan